Ifilimu ye-TPU ene-PET ekhethekileyo ephindwe kabini yefilimu yokukhusela ipeyinti yemoto engeyomthubi ye-PPF

Malunga nefilimu yeTPU

Isiseko sezinto eziphathekayo

Ulwakhiwo: Eyona nto iphambili eyenziweyo kwifilimu engenanto yeTPU yi-thermoplastic polyurethane elastomer, eyenziwe yi-reaction polymerization yee-molecules ze-diisocyanate ezifana ne-diphenylmethane diisocyanate okanye i-toluene diisocyanate kunye nee-polyols ze-macromolecular kunye nee-polyols ze-molecular ezisezantsi.

Iimpawu: Phakathi kwerabha neplastiki, enoxinzelelo olukhulu, uxinzelelo olukhulu, oluqinileyo nolunye

Inzuzo yesicelo

Khusela ipeyinti yemoto: ipeyinti yemoto yahlulwe kwindawo engaphandle, ukuze kuthintelwe ukubola komoya, ukubola kwemvula ene-asidi, njl.njl., kurhwebo lweemoto ezisetyenzisiweyo, inokukhusela ngempumelelo ipeyinti yokuqala yesithuthi kwaye iphucule ixabiso lesithuthi.

Ulwakhiwo olulula: Ngokuguquguquka okuhle nokulula, ingangena kakuhle kumphezulu ogobileyo wemoto, nokuba yiplani yomzimba okanye inxalenye ene-arc enkulu, inokufikelela ekuqineni okuqinileyo, ulwakhiwo olulula, ukusebenza kakuhle, kwaye inciphise iingxaki ezifana namaqamza kunye nokugoba kwinkqubo yokwakha.

Impilo yokusingqongileyo: Ukusetyenziswa kwezinto ezinobuhlobo nokusingqongileyo, ezingenabungozi nezingenancasa, ezinobuhlobo nokusingqongileyo, ekuvelisweni nasekusetyenzisweni kwenkqubo akuyi kubangela umonakalo emzimbeni womntu nakwindalo esingqongileyo.

Isicelo

Izicelo: Ingaphakathi leemoto kunye neengaphandle, ifilimu yokukhusela izindlu zezixhobo ze-elektroniki, ii-dressing ze-catheter zonyango, impahla, izihlangu, ukupakishwa

Iiparameters

Amaxabiso angasentla aboniswa njengexabiso eliqhelekileyo kwaye akufuneki asetyenziswe njengeenkcukacha.

| Into | Iyunithi | Umgangatho wovavanyo | Inkcazo. | Isiphumo soHlahlelo |

| Ubukhulu | um | GB/T 6672 | 130±5um | 130 |

| Ukuphambuka kobubanzi | mm | GB/ 6673 | 1555-1560mm | 1558 |

| Tensile strength | I-Mpa | I-ASTM D882 | ≥45 | 63.9 |

| Ukwandiswa ngexesha lokuphumla | % | I-ASTM D882 | ≥400 | 554.7 |

| Ukuqina | Unxweme A | I-ASTM D2240 | 90±3 | 93 |

| Amandla okuxovula i-TPU kunye ne-PET | gf/2.5CM | GB/T 8808 (180.) | <800gf/2.5cm | 280 |

| Indawo yokunyibilika | ℃ | UKofler | 100±5 | 102 |

| Ukuhanjiswa kokukhanya | % | I-ASTM D1003 | ≥90 | 92.8 |

| Ixabiso lenkungu | % | I-ASTM D1003 | ≤2 | 1.2 |

| Ukufota | Inqanaba | I-ASTM G154 | △E≤2.0 | Akukho mthubi |

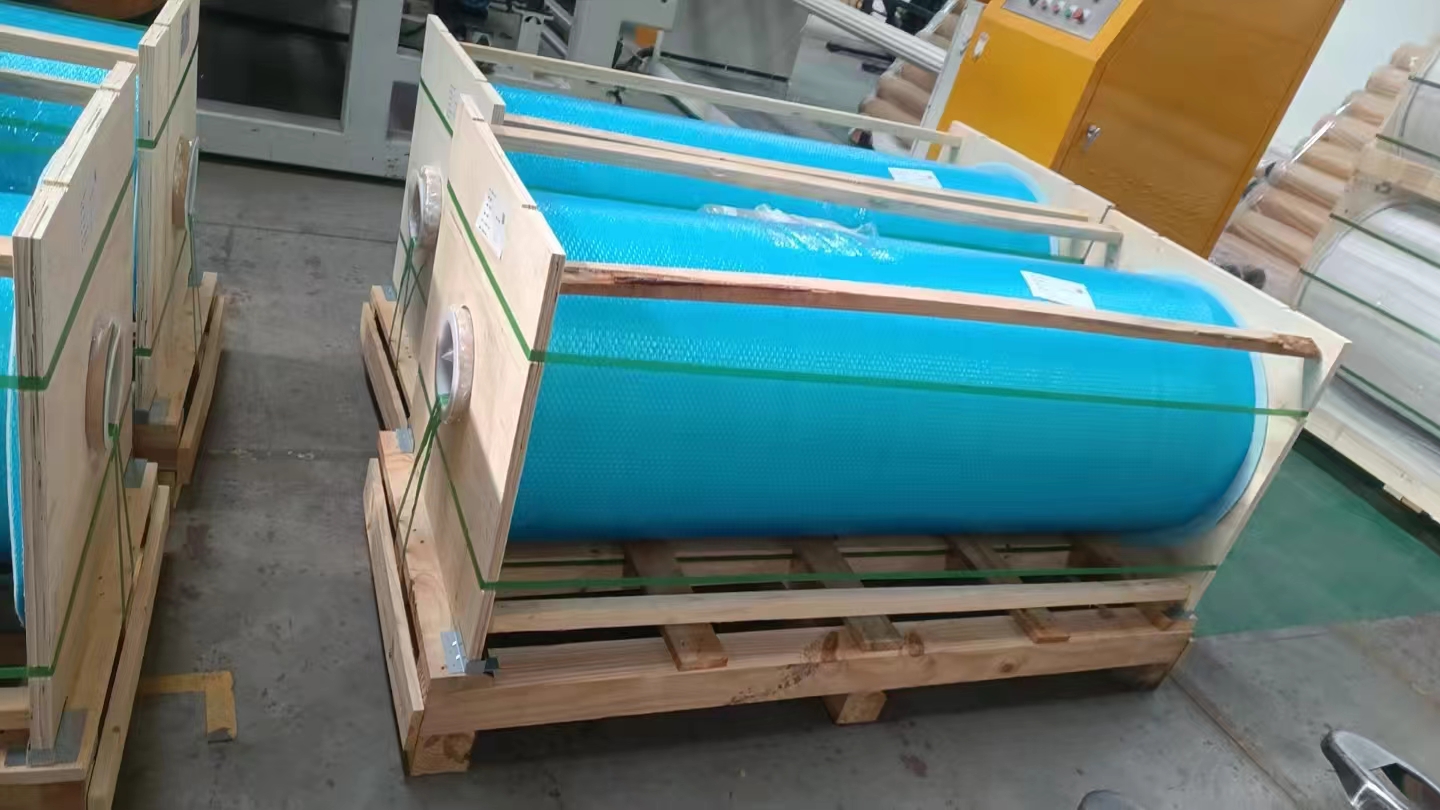

Iphakheji

1.56mx0.15mmx900m/umqulu,1.56x0.13mmx900/umqulu, isetyenzisiweiplastikiipalethi

Ukuphatha kunye nokugcina

1. Kuphephe ukuphefumla umsi kunye nomphunga osebenza ngobushushu

2. Izixhobo zokuphatha oomatshini zinokubangela ukwakheka kothuli. Kuphephe ukuphefumla uthuli.

3. Sebenzisa iindlela ezifanelekileyo zokumisa umhlaba xa uphatha le mveliso ukuze uphephe ukutshaja ngombane

4. Iipellets eziphantsi zingaba zityibilizi kwaye zibangele ukuwa

Iingcebiso zokugcina: Ukuze ugcine umgangatho wemveliso, gcina imveliso kwindawo epholileyo neyomileyo. Yigcine kwisikhongozeli esivalwe kakuhle.

Iziqinisekiso